Purity AOP Disinfects and Clarifies Water without Chemical Residuals

Purity AOP Disinfects and Clarifies Water without Chemical Residuals

Our AOP uses metal where others use fragile plastic; our layout is perfect for easy maintenance; our components deliver more hydroxyl radical cleaning power.

1. PURITY AOP DISINFECTS AND CLARIFIES WATER WITHOUT CHEMICAL RESIDUALS

AOP WHAT IS ADVANCED OXIDATION PROCESS uses no chemicals and leaves no residual, while also easily outperforming outdated Chlorine in all areas. It is the state-of-the-art in chemical free pool water disinfection and clarification. AOP’s hydroxyl radical obliterates all common harmful pathogens found in recreational water, including Cryptosporidium, Giardia, Norovirus, E. coli, Shigella, Hepatitis A, Legionnaires’ disease, salmonella, etc, all without leaving even a trace of chemicals or negative byproduct in the water. Cryptosporidium, the leading cause of recreational water illness (diarrhea) in the United States, is a particularly dramatic example of AOP’ potency. AOP INSTANTLY destroys Crypto, whereas outdated Chlorine can take up to 10 days to kill Crypto.

Purity AOP reduced pathogens by 99.999% in NSF certification testing. No other AOP system has tested above 99.9%. Mathematically, this means for every infectious pathogen left after 99.999% reduction, 100 infectious pathogens are left after 99.9% reduction.

(100,000 Pathogens Initially)

(Still 100 Pathogens Remaining)

(Only 1 Pathogen Remaining)

Chlorine for swimming pools was developed in the early 1900’s, when the medical profession was still using colloidal silver, copper and mercury derivatives for various illnesses and infections. With the development of penicillin in 1942, medicine abandoned mercury, copper, colloidal silver and other archaic treatments. But chlorine has continued to hang around in spite of its numerous and harmful side-effects. No more!

CHLORINE: Chlorine has numerous negative side effects, including dry and itchy skin, brittle nails, red irritated eyes, nasal irritation, coughing and wheezing, bad hair and scalp, yellow teeth and weakened swimsuit fabrics, to name just a few. Swimmers with preconditions such as cellulitis, eczema, asthma, chronic obstructive pulmonary disease and other respiratory conditions, are particularly at risk.

AOP eliminates all the side effects and dangers associated with Chlorine and any other chemical disinfectants. Additionally, AOP is more powerful than ozone and can oxidize certain hard to get organic compounds that ozone alone cannot completely oxidize.

Chlorine costs have skyrocketed especially since 2020 and can be hard to find. With AOP the only chlorine required is enough to keep your pool water at drinking water levels, 0.5ppm, rather than traditional chlorinated pools which require 2-5 ppm.

Purity AOP’s system operates effectively at all flow rates, thanks to our unique patent-pending flow design and components. Other AOP systems on the market can only operate within a narrow range between 30-50 GPM, which severely limits pool size and flow rates eligible for their systems. Purity AOP is the only viable option for variable speed pumps!

Before accessing the connection terminals, ensure that all supply circuits are disconnected.

Check Local ordinances and building codes before installation of equipment. (See A. Technical characteristics)

Installation — Before starting the installation, PLEASE read this manual from cover to cover. A few moments spent initially becoming totally familiar with the Purity AOP system and its installation requirements will save a great deal of time (and expense) later. If you have questions that are not answered after you have completed the reading of this manual, contact your supplier or Purity AOP. We are ready to assist you at any time and we want your installation to go smoothly and the equipment to work properly.

PURITY AOP SYSTEM INSTALLATION

Model PAOP80

Injector (Vessel) Installation Instructions.

** All Plumbing should be performed by a licensed plumber. **

** All electrical work should be performed by a licensed electrician**

IMPORTANT SAFETY INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should always be followed, including the following:

1. READ AND FOLLOW ALL INSTRUCTIONS

2. WARNING – To reduce the risk of injury, do not permit children to use this product unless they are closely supervised at all times.

3. WARNING — DO NOT ENERGIZE THE AOP SYSTEM UNTIL ALL STEPS DETAILED IN THESE INSTRUCTIONS HAVE BEEN COMPLETED.

4. WARNING – Do not breathe the hydroxyl radical gas produced by the AOP System. Inside the delivery hose or reactor

5. WARNING – Risk of Electric Shock. Connect only to a branch circuit protected by a groundfault circuit interrupter (GFCI). Contact a qualified electrician if you cannot verify that the circuit is protected by a GFCI.

6. The unit must be connected only to a supply circuit that is protected by a ground-fault circuit-interrupter (GFCI). Such a GFCI should be provided by the installer and should be tested on a routine basis. To test the GFCI, push the test button. The GFCI should interrupt power. Push the reset button. Power should be restored. If the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts power to the pump without the test button being pushed, a ground current is flowing, indicating the possibility of an electric shock. Do not use this pump. Disconnect the pump and have the problem corrected by a qualified service representative before using.

SAVE THESE INSTRUCTIONS

PURITY AOP INSTALLATION INSTRUCTIONS

1. The Purity AOP system can be used suction side or pressure side. Oxidizing gas from the AOP electrical box is delivered via a 10’ long PTFE hose with Stainless Steel braiding.

2. For suction side, the braided hose can be connected to the drain port of the pump with the supplied ¼” MNPT fitting.

3. For pressure side, the braided hose connects to our injector assembly with the supplied ¼” MNPT fitting.

4. The AOP box should be located close enough to the pump drain port or the injector so the 10’ long hose can easily reach the desired connection.

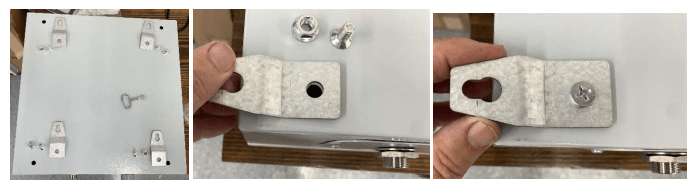

5. The AOP box must be mounted in an upright position. It can be mounted on a wall, rack, fence, or any sturdy surface. Four Mounting tables are included. See illustration below:

ELECTRICAL

WARNING: The incoming power must be OFF before opening the AOP box.

The Purity AOP system is available as either 120VAC, or 240VAC. The voltage is shown on the labels inside the door and next to the mains terminal block.

2. Wire connection on the mains block ate wired G – L – N or G – L – L

3. The total power draw is less than 2 amps.

4. The device should be connected to a relay in the main pool control box, so it is only ON when the filter pump is running Page 8 of 16 Revision 1; IFU 9-26-2024

5. The unit comes with a ½” nonmetallic (Sealtite style) conduit connector.

GAS HOSE

1. The gas from the AOP box is delivered with a PTFE hose with stainless steel braid and vinyl mesh.

2. The gas hose has straight connections installed. They can be replaced with 45 and 90 degree hose connections if desired.

3. 4AN x ¼” NPT adapters are loosely connected to each end of the hose. Use the fitting to connect the hose to the bulkhead located on the bottom of the box and the inlet of the injector.

Purity AOP creates Hydroxyl Radicals in a dry reactor, whereas other leading AOP systems create them in a wet environment. Only Dry Reactors create true AOP Disinfection. Wet Reactor DESIGN cannot assure AOP disinfection, especially in cloudy pool water, for two reasons. First, in a Wet Reactor, the Ozone is exposed to the impurities in the water before it can be converted to the AOP Hydroxyl Radicals and so it is partly/completely consumed before becoming AOP ready. Secondly, water filters UV, weakening the radiation available to convert the remaining Ozone to Hydroxyl Radicals. In a dry reactor, ALL of the Ozone is converted to the AOP Hydroxyl Radical before it is mixed into the water.

Purity AOP starts with producing 80% more Ozone than other AOP systems. 80% more Ozone production means 80% more Ozone available to convert to Hydroxyl Radicals and 80% more disinfection dosage available for cleaner, safer swimming pool water.

Our corona discharge cells are rated at 200-300mg/hour Ozone production, which is 50% higher than other AOP systems. Even under extreme environmental conditions of high temperatures and high humidity our Corona Cells will produce a minimum 200 mg/hour Ozone. Other AOP systems max out at 200 mg/hour under ideal cool weather and low humidity, falling well below 200 in higher heat and humidity.

Engineered to propel gas forward, guaranteeing the delivery of hydroxyl radicals to the injector.

Other AOP systems are severely limited to 30-50 GPM water flow. This creates a severe disadvantage with larger pools and with variable speed pumps. Below 30 GPM and above 50 GPM, the other AOP systems cannot assure that the AOP disinfecting gas will overcome back pressure and get into the water flow.

Purity AOP prevents or eliminates back pressure, thus we can operate at all flow rates. We incorporate a pump to propel disinfecting gas forward. Our reactor and our delivery tube have been engineered to maximize disinfecting gas velocity. And our patent pending proprietary injector also creates negative pressure rather than back pressure at the mixing junction. Together all these design and equipment features guarantee full disinfecting dosage at all flow rates. We are not limited to any specific flow range.

Superior mixing creates more thorough contact with contaminants in the water so that the full power of AOP’s sanitizing and oxidizing can be brought to bear in creating pure and safe swimming pool water. No other injector on the market mixes the AOP gas like Purity AOP.

Purity AOP works equally whether on the pressure side or suction side. Purity AOP’s proprietary design delivers the full hydroxyl radical dose into the pool water either way.”

Purity AOP has a lower cost of ownership than other AOP systems because it uses superior parts that last longer, work more reliably, and do not need constant replacement.

(A) HOSES AND CHECK VALVES. For example, other AOP manufacturers use plastic hoses that corrode under AOP, and cheap plastic check valves with plastic flappers that have a high failure rate. Both components require annual replacement. Purity AOP on the other hand uses only pure Teflon (PTFE) hoses and Kynar fittings, all of which are impervious to AOP, throughout the system. In addition, the delivery hose is protected with a braided stainless steel cover like those on racing motorcyles, so they don’t rupture when they get pinched or stepped on. We also use a robust stainless steel spring loaded check valve which virtually never malfunctions. Both check valve and hoses will need no replacement for the life of the system.

(B)AIR FILTER. Other AOP manufacturers filter incoming air with a tiny 0.049 square inch filter that is easily plugged, shutting down the production of AOP. Purity AOP employs an air filter with 122x more surface area (6 square inches) and which will never plug.

(C)SEALED METAL ENCLOSURE. Other AOP systems are vulnerable to invading insects and ants through the air inlet of the system enclosure. Ants are a particular problem because they can chew their way into wiring and short the electronics. Only Purity AOP uses a sealed NEMA-4 design, limiting access to invading pests and debris with seals and a metal mesh screen across its air inlet on the bottom of the sealed enclosure.

(D)SMART SYSTEM LAYOUT. Other AOP systems can be difficult to work on and maintain. Purity AOP’s system is designed with maintenance contractors in mind. There is easy access for all components. No tools required to change lamp, just open the door, unscrew the lid and replace the lamp.

Purity AOP has a lower cost of ownership because it is designed for durable reliability and for easy access by pool maintenance contractors when necessary. Swimming Pool Maintenance contractors love Purity AOP because it rarely needs service and service calls are easy and straight forward.